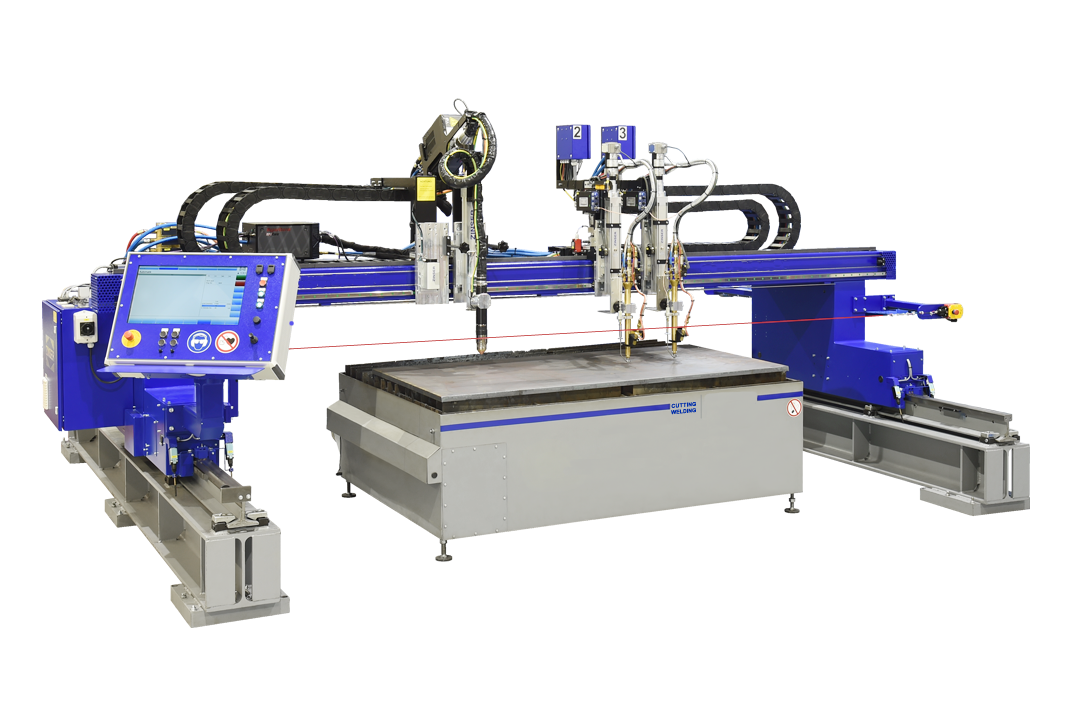

Specifications of OXY-FUEL CUTTING MACHINES

| Parameter | Typical Specification |

| Cutting Method | Oxy-Acetylene / Oxy-Propane / Oxy-Natural Gas |

| Material Cut | Mild Steel / Carbon Steel (not suitable for stainless or aluminum) |

| Cutting Thickness | 3 mm – 300 mm (some machines can cut up to 1000 mm with multiple torches) |

| Cutting Speed | 100 – 1000 mm/min (depends on material and thickness) |

| Torch Type | Manual / Automatic / Multi-torch |

| Gas Pressure (Oxygen) | 2 – 6 bar (typically) |

| Gas Pressure (Fuel) | 0.5 – 2 bar (varies with gas type) |

| Nozzle Type | Single or Multi-flame nozzles (based on material thickness) |

| Torch Height Control | Manual / Automatic (with Capacitive or Flame Sensor) |

| Ignition System | Manual Spark / Automatic Electric Ignition |

| Bevel Cutting Capability | Yes (with adjustable torch angles) |

| Drive System | Manual / Motorized / CNC (for profile cutting) |

| Control Panel | Basic analog / Digital / CNC with G-code input (for CNC models) |

| Cooling System | Air-cooled (no liquid cooling required) |