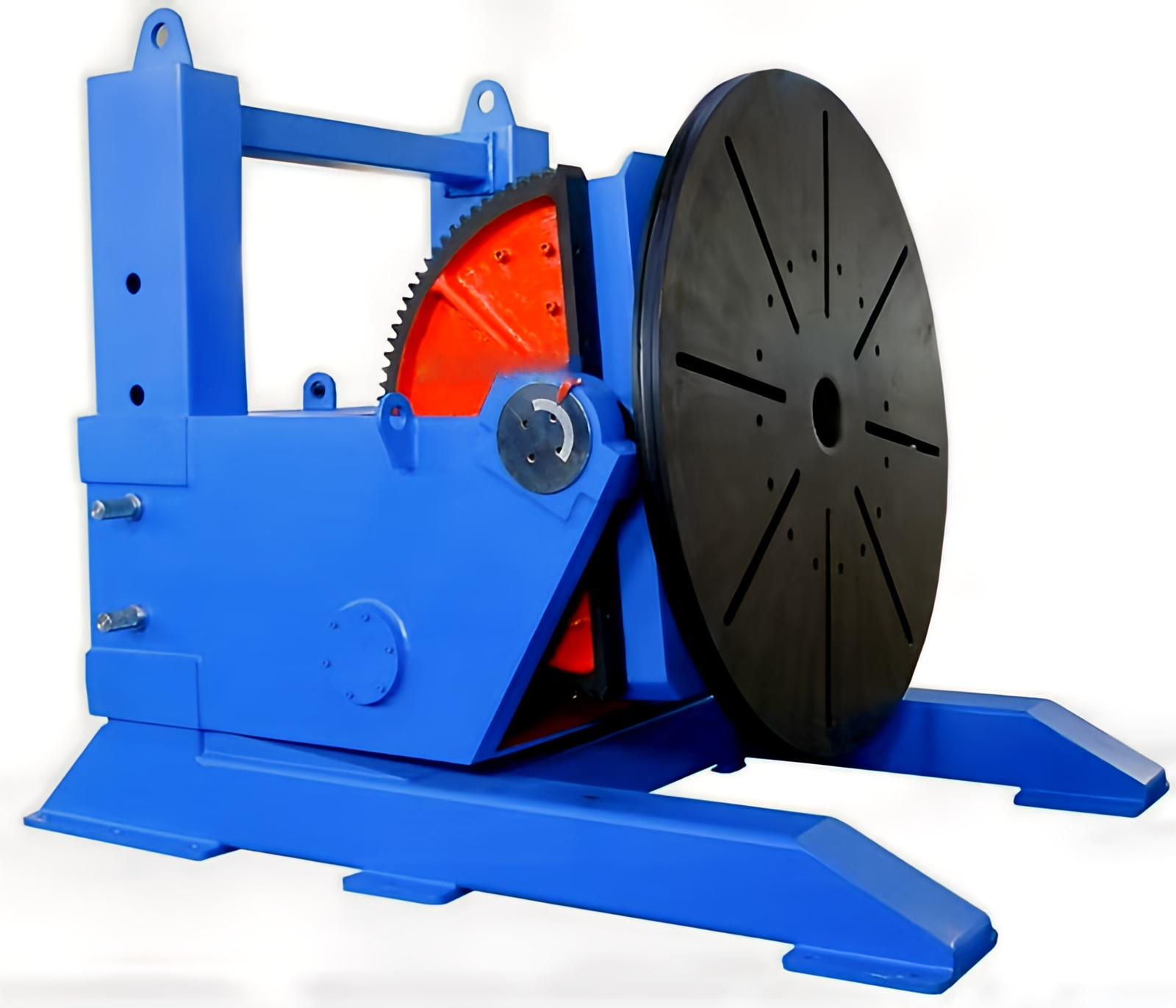

Specifications of TURNING MACHINE (2-Axis)

| Parameter | Specification |

| Machine Type | CNC Turning Center (2-Axis) |

| Max Turning Diameter | 200 mm to 500 mm |

| Max Turning Length | 300 mm to 1000 mm |

| Swing Over Bed | 400 mm to 600 mm |

| Spindle Bore | 45 mm to 90 mm |

| Spindle Speed | Up to 4000–6000 RPM |

| Spindle Motor Power | 7.5 kW to 15 kW |

| Chuck Size | 6″ / 8″ / 10″ |

| Turret Type | 8 / 12 Station Servo or Hydraulic Turret |

| Tool Shank Size | 20 mm x 20 mm (Square tool) |

| Control System | FANUC / Siemens / Mitsubishi |

| X-Axis Travel | 150 mm to 300 mm |

| Z-Axis Travel | 300 mm to 1000 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tailstock | Programmable or Manual (optional) |

| Bar Capacity (for bar-fed models) | 40 mm to 75 mm |

| Coolant System | Yes, with filtration system |

| Machine Weight | 2500 kg to 5000+ kg |

| Power Supply | 415V / 3 Phase / 50 Hz |